The probability is 1 that an electrical connector will perform its intended function, making it a crucial component in any electrical system. Understanding the factors that influence this probability is essential for ensuring the reliability and safety of electrical connections.

Electrical connectors come in various types, each with its advantages and disadvantages. The design of a connector, including the materials used and the testing methods employed, also plays a significant role in determining its probability of failure.

Electrical Connector Probability

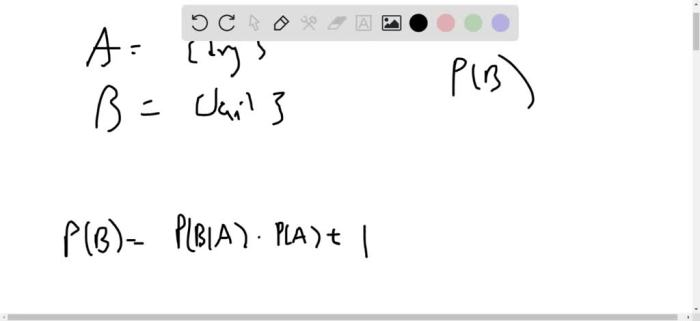

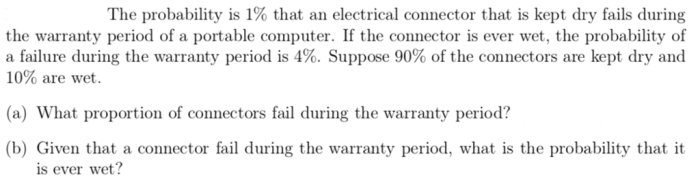

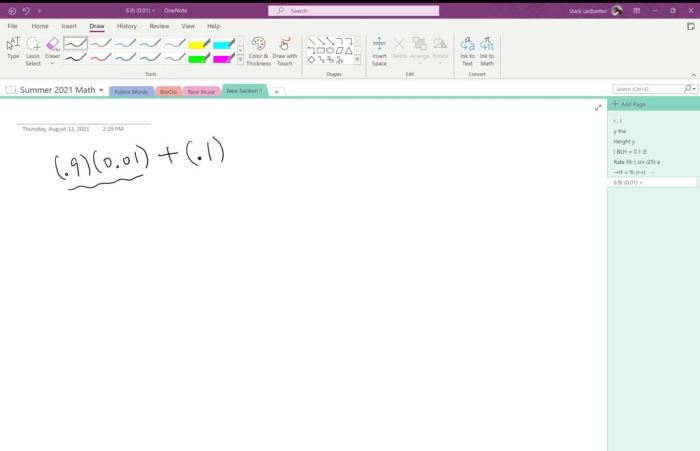

Probability is a measure of the likelihood of an event occurring. In the context of electrical connectors, probability can be used to assess the reliability of a connector. The probability of an electrical connector failure is determined by a number of factors, including the type of connector, the materials used in its construction, and the environmental conditions in which it is used.

One way to assess the probability of an electrical connector failure is to use a failure rate. A failure rate is the number of failures that occur per unit of time. The failure rate of an electrical connector can be used to predict the probability of failure over a given period of time.

Another way to assess the probability of an electrical connector failure is to use a reliability curve. A reliability curve shows the probability of failure over time. The reliability curve for an electrical connector can be used to predict the probability of failure at any given point in time.

Types of Electrical Connectors

There are many different types of electrical connectors available. Each type of connector has its own advantages and disadvantages.

- Crimp connectorsare the most common type of electrical connector. They are easy to install and are relatively inexpensive.

- Solder connectorsare more reliable than crimp connectors, but they are more difficult to install and require specialized equipment.

- Screw connectorsare a good choice for high-current applications. They are easy to install and can be reused multiple times.

- Spring connectorsare a good choice for applications where space is limited. They are easy to install and can be used with a variety of wire gauges.

Electrical Connector Design, The probability is 1 that an electrical connector

The design of an electrical connector is critical to its reliability. The following are some of the key design considerations for electrical connectors:

- The type of connector: The type of connector will determine the materials used in its construction and the environmental conditions in which it can be used.

- The materials used in its construction: The materials used in the construction of an electrical connector will affect its durability and reliability.

- The environmental conditions in which it will be used: The environmental conditions in which an electrical connector will be used will affect its reliability.

Electrical Connector Testing

Electrical connectors should be tested to ensure that they meet the required specifications. The following are some of the tests that can be performed on electrical connectors:

- Insulation resistance test: This test measures the resistance between the conductor and the insulator.

- Dielectric withstand test: This test measures the ability of the insulator to withstand a high voltage without breaking down.

- Contact resistance test: This test measures the resistance between the contacts.

- Mechanical strength test: This test measures the ability of the connector to withstand mechanical stress.

Electrical Connector Applications

Electrical connectors are used in a wide variety of applications. The following are some of the most common applications for electrical connectors:

- Power distribution: Electrical connectors are used to distribute power from the source to the load.

- Signal transmission: Electrical connectors are used to transmit signals from one device to another.

- Data transmission: Electrical connectors are used to transmit data from one device to another.

- Control systems: Electrical connectors are used to control the operation of devices.

Q&A: The Probability Is 1 That An Electrical Connector

What factors affect the probability of electrical connector failure?

Environmental conditions, mechanical stress, material degradation, and manufacturing defects can all contribute to electrical connector failure.

How can the probability of electrical connector failure be minimized?

Proper design, selection of suitable materials, rigorous testing, and adherence to industry standards can help minimize the probability of failure.

What are the consequences of electrical connector failure?

Electrical connector failure can lead to power outages, equipment damage, safety hazards, and data loss.